Ваша заявка принята!

Наш менеджер свяжется с Вами

в течение 2 минут!

Рабочее время 8:00-17:00 (МСК)

Краткое описание товара

| Specifications | Units of phys. qt | Standard size | ||

| Boiler type | 20 | |||

| Heating capacity | kW | 20000 | ||

| Water temperature | at the exit of the boiler | ◦С | 110 | 150 |

| at the entrance to the boiler | 70 | 70 | ||

| EC (efficiency coefficient) of boiler | Natural gas | % | 94,6 | 93,4 |

| fuel oil | 92,5 | 91,3 | ||

| Fuel consumption | Natural gas | Nm3/h | 2113 | 2137 |

| fuel oil | kg/h | 2001 | 2025 | |

| Exhaust gas temperature | Natural gas | ◦С | 140 | 163 |

| fuel oil | 176 | 200 | ||

| Aerodynamic resistance of the boiler (without burner) | Pa | 1200 | 1230 | |

| Hydraulic resistance | MPа | 0,13 | 0,12 | |

| Design water pressure at the inlet | MPа | 0,9 | 1,6 | |

| Water flow through the boiler | t/h | 430 | 215 | |

| Specific emission of nitrogen oxides | Natural gas | g/m³ | 0,08 | 0,08 |

| fuel oil | 0,26 | 0,26 | ||

| Adjustment range | % | 30-100 | 30-100 | |

| Boiler weight (without burner, without water) | kg | 25570 | 25270 | |

| Water volume of boiler | m³ | 5 | 5 | |

| Heating surface area | m² | 745 | 745 | |

GEOTHERM ® WMB series boilers are designed to produce hot water. Boilers are focused on heat supply of industrial and domestic facilities.

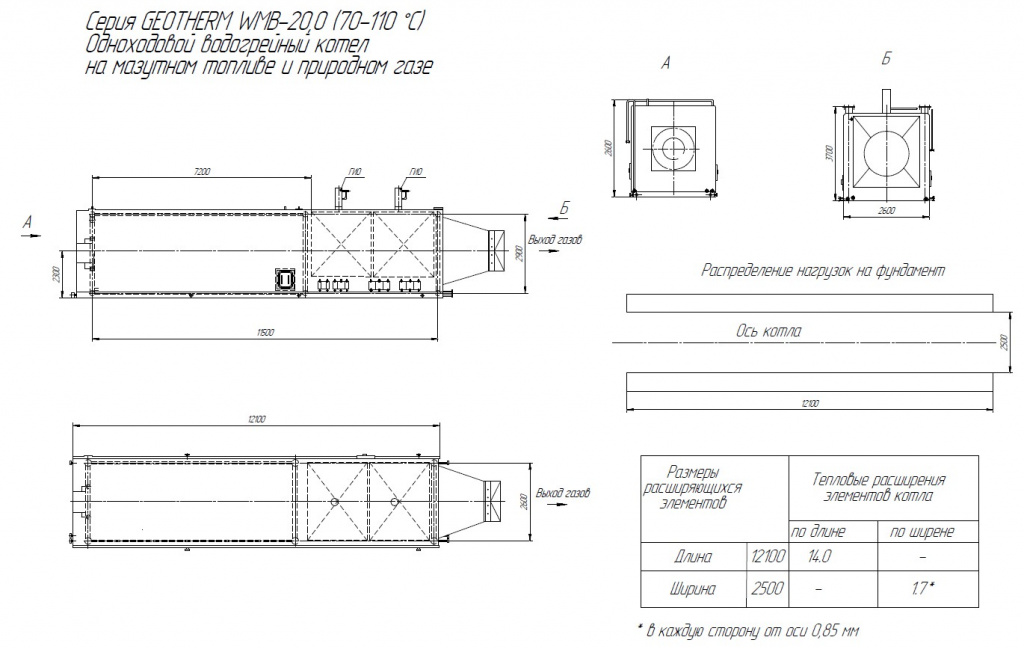

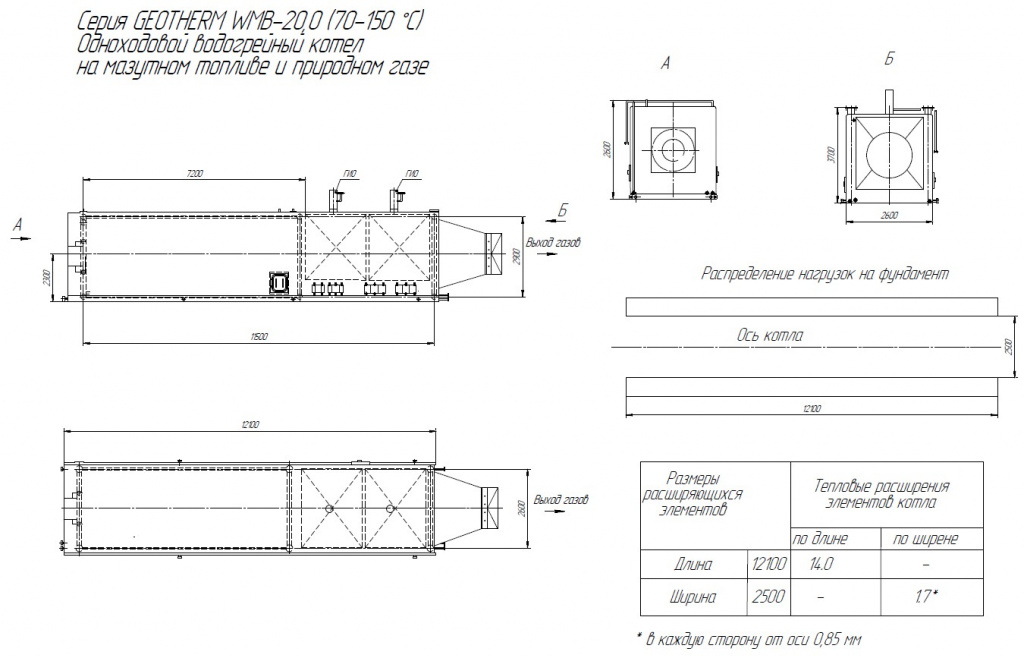

GEOTHERM ® WMB series boilers are produced with three temperature schedules 70-95 °C; 70-110 °C; 70-150 °C.

GEOTHERM ® WMB series boilers are produced with a capacity from 0.63 to 35.0 MW.

The fundamental difference between the GEOTHERM ® WMB series boilers and the GEOTHERM WGB(3P); GEOTHERM WGB(P); GEOTHERM WGB(V) series boilers is that an intermediate collector is provided in the pipe system and niches for ash removal are located under the convective part. An intermediate collector is necessary to increase the pitch in the convective surface, this avoids clogging of the convective surface with fuel oil. The niches are designed to remove ash residue that forms on the convective surface during the combustion of fuel oil. The main advantage of boilers of this series is that they can run on fuel oil.

The main components of the GEOTHERM ® WMB series boilers:

Collector frame - serves to distribute water flows depending on the hydraulic circuit of the boiler and the connection of the boiler to the external strapping.

The convective section is the main part of the boiler pipe system.

The support frame serves as the base for the installation of the boiler pipe system.

Stiffness belt - serves as a frame to ensure the rigidity of the boiler.

In the design of the GEOTHERM WMB 20 boiler, an additional collector is provided and the pitch of the convective panels is increased, this avoids clogging of the convective surface.

Рабочее время 8:00-17:00 (МСК)

Рабочее время 8:00-17:00 (МСК)

Рабочее время 8:00-17:00 (МСК)

Рабочее время 8:00-17:00 (МСК)

Нажимая на кнопку, Вы даете согласие на обработку персональных данных.The model is under development and will soon appear on the site.