It is not always possible to provide industrial premises with heating and hot water supply using centralized systems, due to the technical features of the facility.

Our site presents a large selection of industrial hot water boilers, from small power, sufficient for mini-enterprises to powerful hot water heat generators that can cope with the full heating of urban areas or large-scale industrial complexes.

The device of industrial boilers

The general principle of operation of hot water industrial heating equipment is not much different from conventional household boilers. The difference is only in higher power ratings and larger dimensions of such installations, which is fully consistent with the purpose and design of a hot water boiler of this scale.

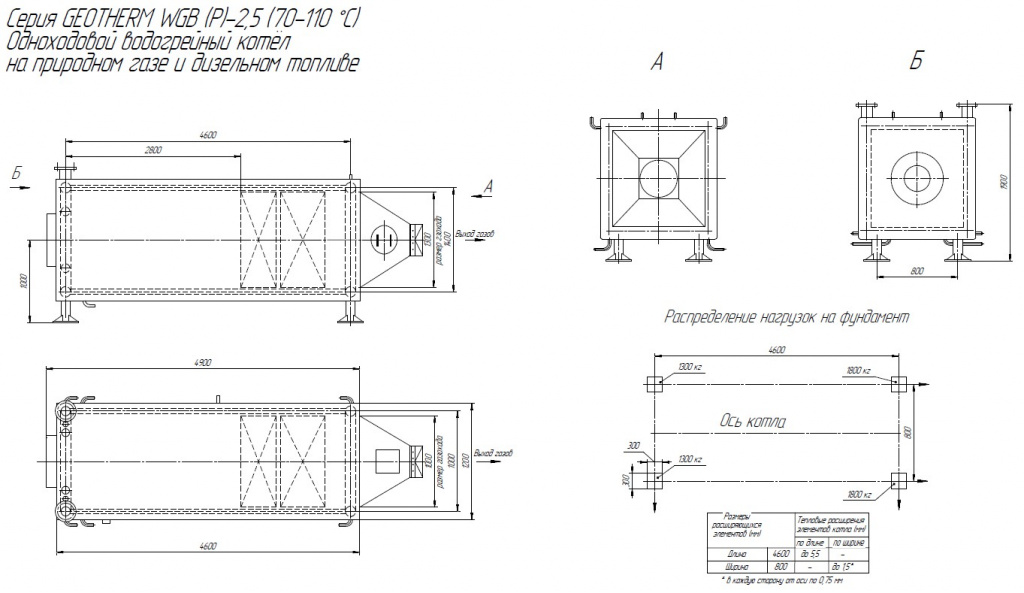

The composition of hot water boilers includes a combustion chamber, a block of convective panels through which the coolant circulates, a support frame and stiffening belts. When a gas or solid fuel is completely burned, thermal energy is formed, which is transferred to the coolant through the walls of the heat exchanger pipes. The firebox itself is most often made of steel panel elements. As a rule, to seal these components and increase heat transfer, they are made gas-tight by welding special strips between the pipes.

The temperature maximum inside the furnace can reach up to 1200 degrees. Leaving the furnace, the hot gas usually passes into the convection unit with special compartments. For maximum heat transfer, the pipes are arranged in a checkerboard pattern.

Thanks to the efficient operation of the hydraulic system of hot water boilers, the coolant not only heats up, but also moves a little faster to reduce the risk of scale and stagnant processes. To do this, the system has special partitions that operate on the speed of transporting the water resource through the system. This design of hot water boilers proved to be excellent in practice. The inlet and outlet of the coolant are brought to the frontal rear surface of the boiler.

Benefits of using industrial hot water boilers

Modern industrial hot water boilers are made in accordance with high quality standards, so they have a number of advantages:

-

Security. The automation system, shut-off and control valves and instrumentation provide maximum safety in operation.

-

Efficiency. A high efficiency factor allows you to economically spend fuel resources and at the same time receive high-quality heating.

-

Simplicity and reliability of operation. For the smooth operation of the heating unit, it is necessary to carry out maintenance activities in a timely manner.

The selection of such industrial equipment should be approached very seriously, and for the calculation of the boiler, you can seek help from our professionals.