ECO-SPECTRUM LLC occupies a leading position in the production of incinerators for waste disposal and neutralization on the territory of the Russian Federation.

In 2021, the Governor of the Krasnodar Territory stated the high environmental orientation, uniqueness, and merits in the field of industrial design of installations for thermal neutralization and disposal of industrial and consumer waste, medical and biological HURIKAN and VOLKAN series, notably addressing the merits in the nomination of "Exporter of the Year in industry" (see Figure 1,2)

Figure 1,2 - the "Exporter of the Year among small and medium-sized businesses" competition in the field of industrial equipment production

Production facilities and an individual approach to the design of each installation allowed us to expand the geography of deliveries outside the Russian Federation.

In 2021, the company successfully implemented more than 150 projects, and already set out to increase the supply of innovative products to East - Saudi Arabia, UAE, Oman, Iraq, Tunisia and the Middle East, Eastern regions, India, Belarus, Serbia, Peru, as well as Moldova, Kyrgyzstan, Kazakhstan and Greece.

The company's team strives to provide an individual approach to each client, based on their requirements and type of waste. Eco-Spectrum LLC guarantees the environmental friendliness of the equipment, there is no smoke and smell during operation, the availability of State environmental expertise on the equipment ensures the legality of the use of MSW installations.

Each implemented project is an opportunity to find innovative solutions and use non-standard capacities.

In 2021, the company implemented a number of unique solutions determined by economic and environmental expediency: reduction of the fee for NIE (negative impact on environment), avoidance of fees for the accumulation of production and consumption waste, and so on.

1. A strategy has been worked out for the introduction of a three-stage gas purification system - dry gas purification - based on the installation of the H150 incinerator:

- The first stage allows the deposition of a large fraction of suspended particles using a cyclone;

- At the second stage, the gas is cleaned through a bag filter, for fine gas purification, where the bag filter is equipped with a regeneration system (self-cleaning);

- The third stage - allows gas purification from gaseous impurities by absorption of heavy metals.

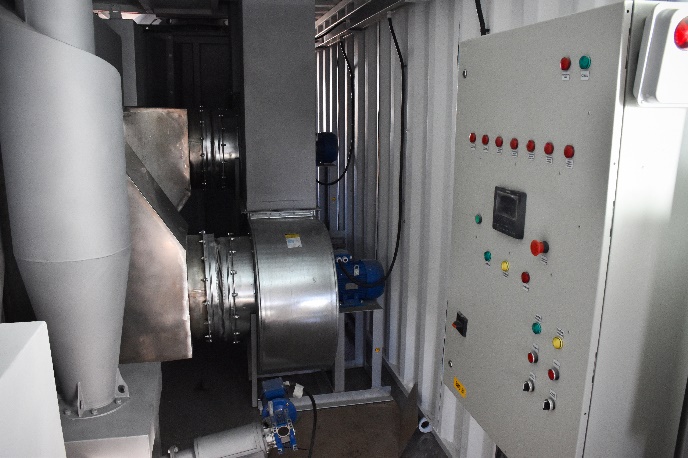

Figure 3.4 - Installation of H150

2. Innovations in the water treatment system have been successfully implemented, as well as a system for gas analysis has been introduced, - based on the installation of H500, - improvement of the loading system:

- Introduction of a hydraulic loading system using a hydraulic pusher;

- Use of a wet cooling tower in a water treatment system;

- Introduction of a gas analyzer and flow meter to control maximum and average daily emissions.

Figure 5,6 - installation of H500

3. The system of water treatment of the circulating cycle on the basis of flotators is applied, - in line with the installation of H400R.

4. Developed by our own R&D department and produced a modular installation of the H200R incinerator in two versions - stationary (modular) and on a mobile frame:

- The H200R unit is equipped with the adjustment of the rotation speed of the main chamber, to ensure optimal waste disposal modes.

- Successfully passed laboratory tests on flue gas measurements;

Figure 7,8 - modular installation of H200R

5. The installation of the H200 has been upgraded and brought into a new version.

- Modernization of the afterburning chamber;

- Equipped with an additional hatch for camera maintenance.

Figure 9.10 - new version of the installation of H200.

ECO-SPECTRUM LLC creates effective ecological and economic solutions with robust adaptation to environmental regulations, the company is constantly seeking new methods and approaches to implementing improvements to reduce generated waste.

We want to inspire by conducting environmental policy in the field of industrial production, and also strive to expand the types of production activities in the field of industrial design.