Ваша заявка принята!

Наш менеджер свяжется с Вами

в течение 2 минут!

Рабочее время 8:00-17:00 (МСК)

| Specifications | Units of phys. qt | Standard size | ||

| Boiler type |

11,63 |

|||

| Heating capacity | kW |

11630 |

||

| Water temperature | at the exit of the boiler | ◦С | 110 |

150 |

| at the entrance to the boiler |

70 |

70 |

||

| EC (efficiency coefficient) of boiler | Natural gas | % |

94,8 |

93 |

| diesel |

92,6 |

91,3 |

||

| Fuel consumption | Natural gas | Nm3/h |

1226,4 |

1242 |

| diesel | kg/h | 1065,1 |

1078,1 |

|

| Exhaust gas temperature | Natural gas | ◦С |

134 |

181 |

| diesel |

174 |

199 |

||

| Aerodynamic resistance of the boiler (without burner) | Pa |

1650 |

1700 |

|

| Hydraulic resistance | MPа |

0,19 |

0,206 |

|

| Design water pressure at the inlet | MPа |

0,9 |

1,6 |

|

| Water flow through the boiler | t/h |

250 |

125 | |

| Specific emission of nitrogen oxides | Natural gas | g/m³ |

0,08 |

0,08 |

| diesel |

0,16 |

0,16 | ||

| Adjustment range | % |

30-100 |

30-100 |

|

| Boiler weight (without burner, without water) | kg |

16000 |

16000 |

|

| Water volume of boiler | m³ |

2,1 |

2,1 |

|

| Heating surface area | m² |

322,3 |

322,3 |

|

GEOTHERM ® WGB (3P) series boilers are designed to produce hot water. Boilers are focused on heat supply of industrial and domestic facilities.

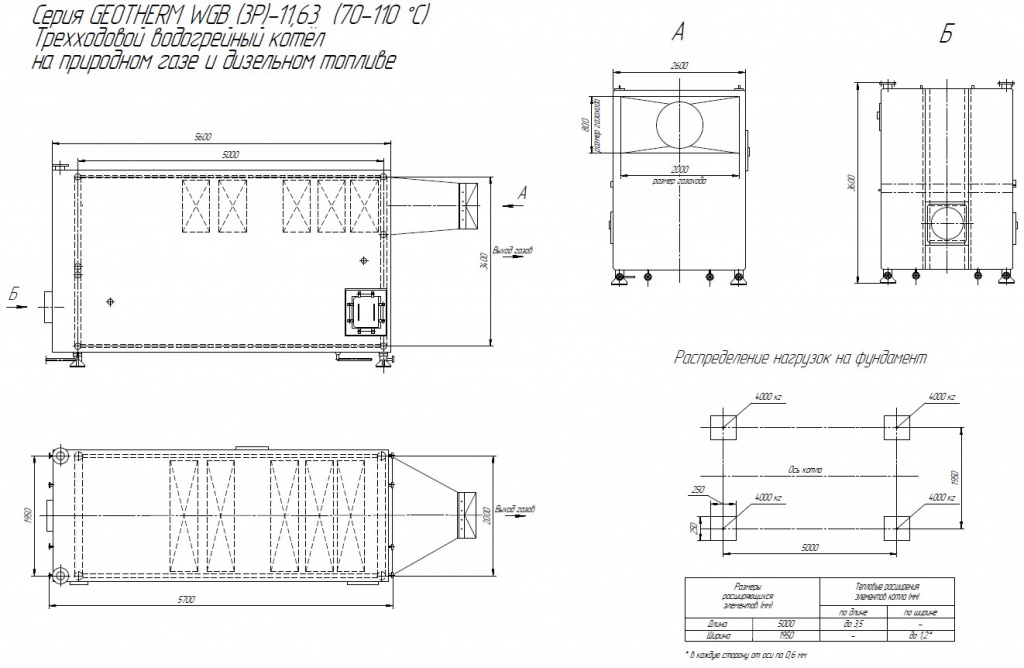

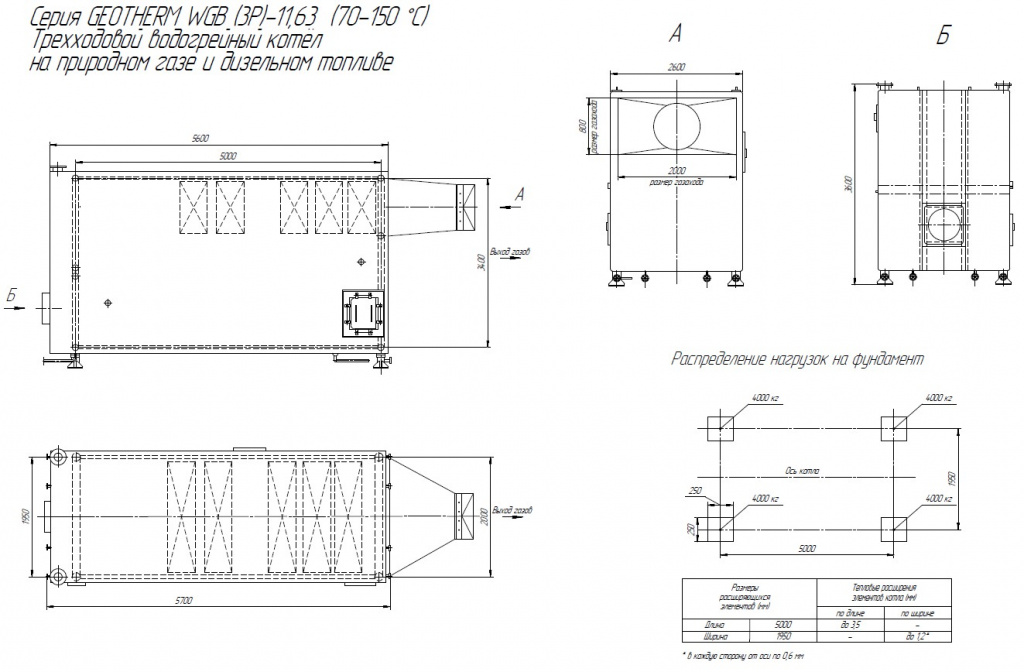

GEOTHERM ® WGB (3P) series boilers are produced with three temperature schedules 70-95 °C; 70-110 °C; 70-150 °C.

Boilers of the GEOTHERM ® WGB (3P) series are produced with a capacity of 0.25 to 15 MW.

The fundamental difference between the boilers of the GEOTHERM ® WGB (3P) series from the boilers of the GEOTHERM WGB(P); GEOTHERM WMB; GEOTHERM WGB(V) series is that the exhaust gases after burning the torch of the burner unfold in the furnace, pass through the fiston, unfold again and pass through the convective surface. The main advantage of boilers of this series is that they can be used to replace old equipment during the reconstruction of boiler houses because boilers of the GEOTHERM ® WGB (3P) series have a small overall size in length. The small overall size in length is achieved by the fact that the convective surface is located above the boiler furnace, and not behind it as in GEOTHERM ® WGB (P) series boilers.

Main components of GEOTHERM ® WGB (3P) series boilers:

The flue duct with an explosive valve - serves as a channel for the discharge of exhaust gases.

The design of the combustion chamber and the efficient combustion of fuel with modern automated burners allows achieving low emissions of nitrogen oxides.

Рабочее время 8:00-17:00 (МСК)

Рабочее время 8:00-17:00 (МСК)

Рабочее время 8:00-17:00 (МСК)

Рабочее время 8:00-17:00 (МСК)

Нажимая на кнопку, Вы даете согласие на обработку персональных данных.