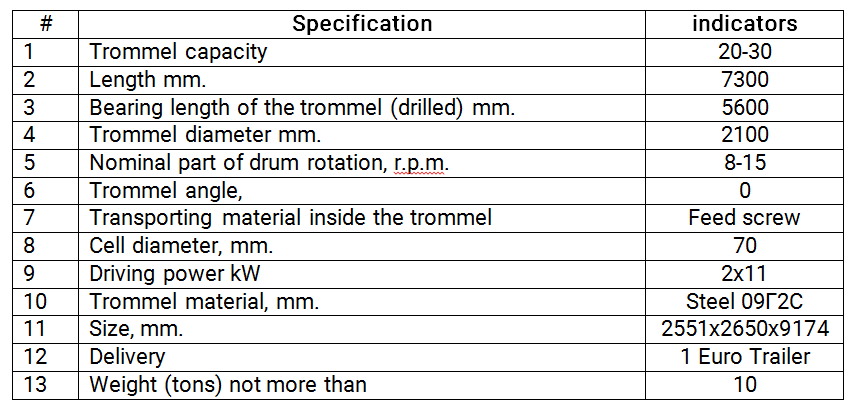

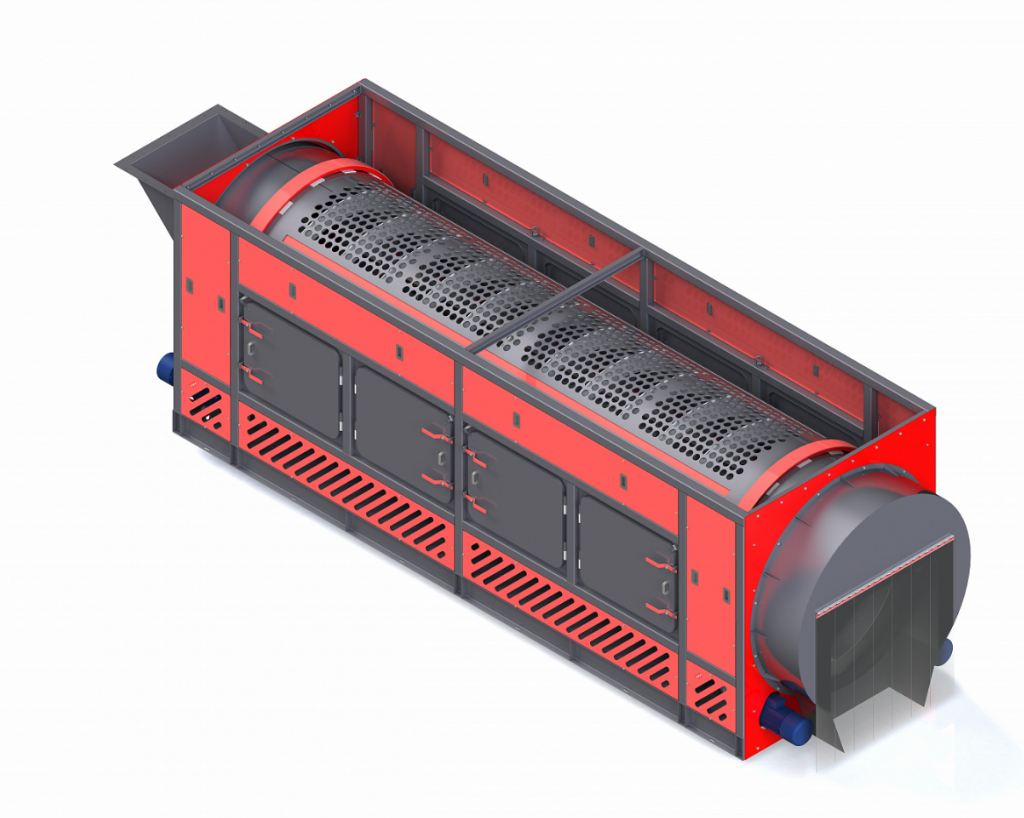

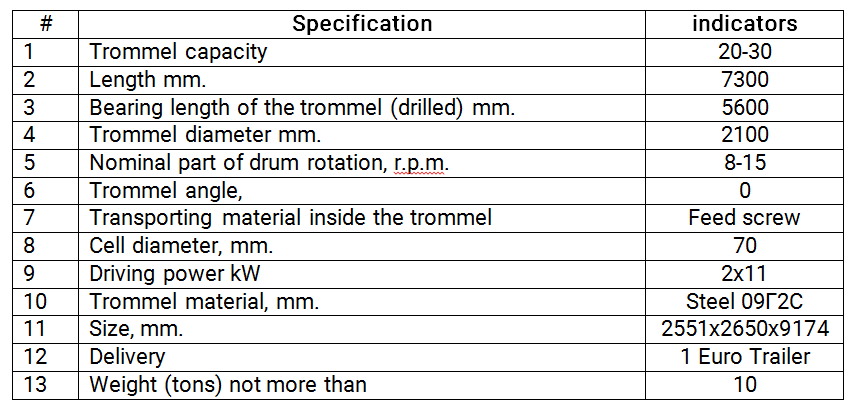

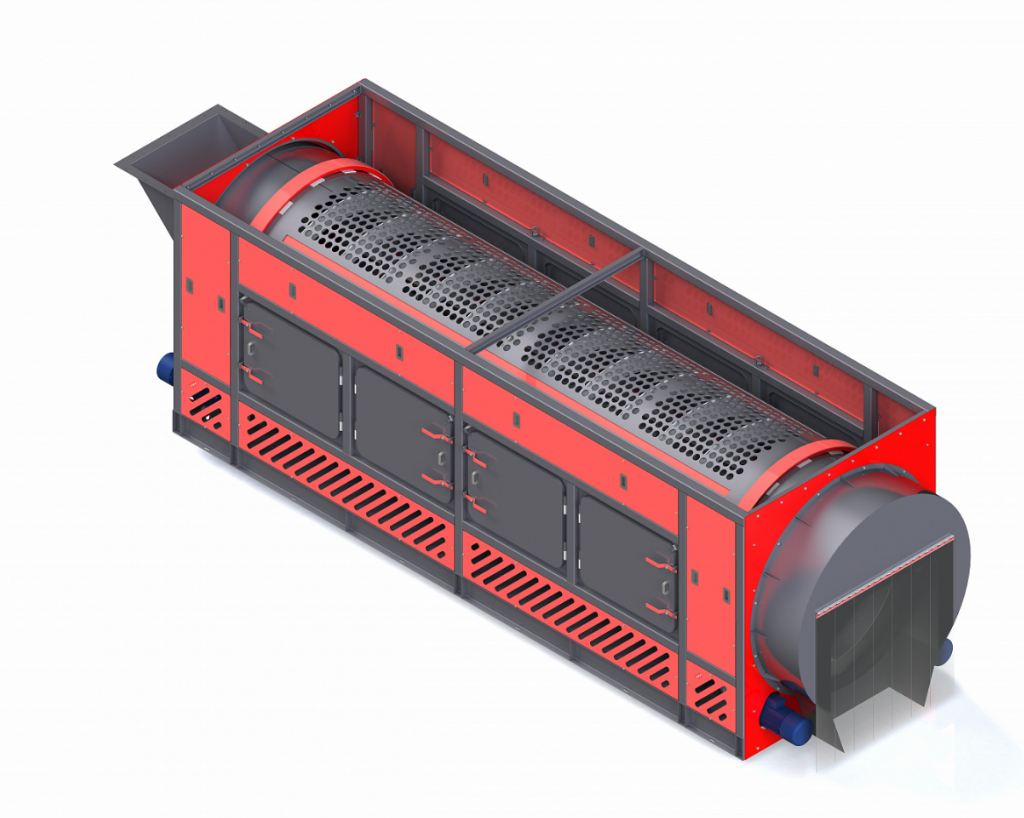

Trommel screen equipment as part of a waste sorting complex designed to separate the fine organic fraction of solid household waste from solid municipal waste by sifting raw material fractions through the walls of a metal drum installed at an angle, rotating using support rollers.

Operation principle of trommel screens

Solid household and municipal waste should be loaded into the hopper of the screening drum. The waste inside the trommel rotates consequently and it is divided into fractions while passing through the holes of the trommel. The fine fraction that goes through the cells of the drum, enters the discharge conveyor and is discharged into a container for further removal to the landfill. A large part goes to the next stage of the production cycle. Inside the screen there is a screw, the blades of which are arranged in a spiral. They are fixed on the inner surface of the cylinder, this provides better sorting due to the even distribution of waste over the inner surface of the cylinder and better screening of small objects and fractions consisting of biological waste, street dust, etc. In addition, the design of the screen prevents the rolling of flat objects, such as pieces of plastic film and cardboard, along the inner wall, this is observed when the screen is inclined. The protrusions on the auger blades provide a constant loosening of the waste, that improves the quality of sorting.

Areas of application of trommel screens

As a rule, this type of trommel screen is used in the secondary processing of the construction, mining and woodworking industries for sorting various materials into fractions.

Recently, trommel screens have been actively used by enterprises involved in the recycling of garbage and various waste products. For example, one of the latest innovations in utilities and waste management is a trommel separator with a magnetic separation function that allows you to capture and separate metal-containing components from other objects.

Advantages of ECOSPECTRUM Trommel SkyScreen'8

1. Maintenance

One of the advantages of the trommel screen is the easy maintenance of the main components, namely:

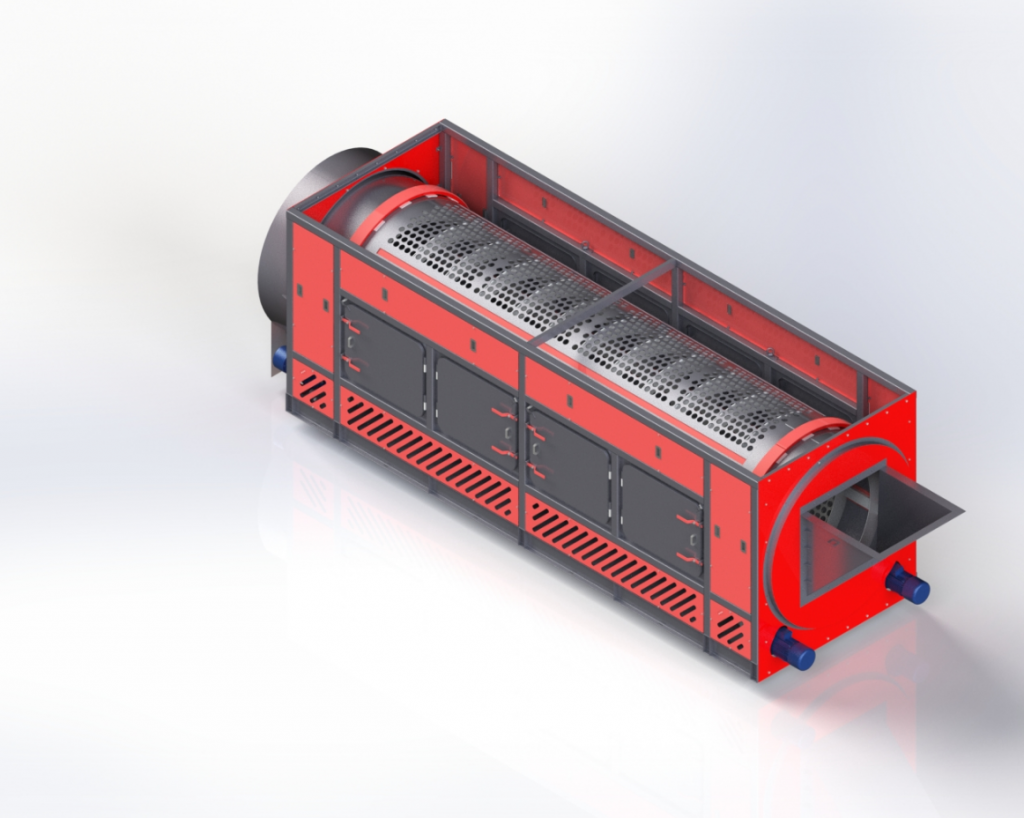

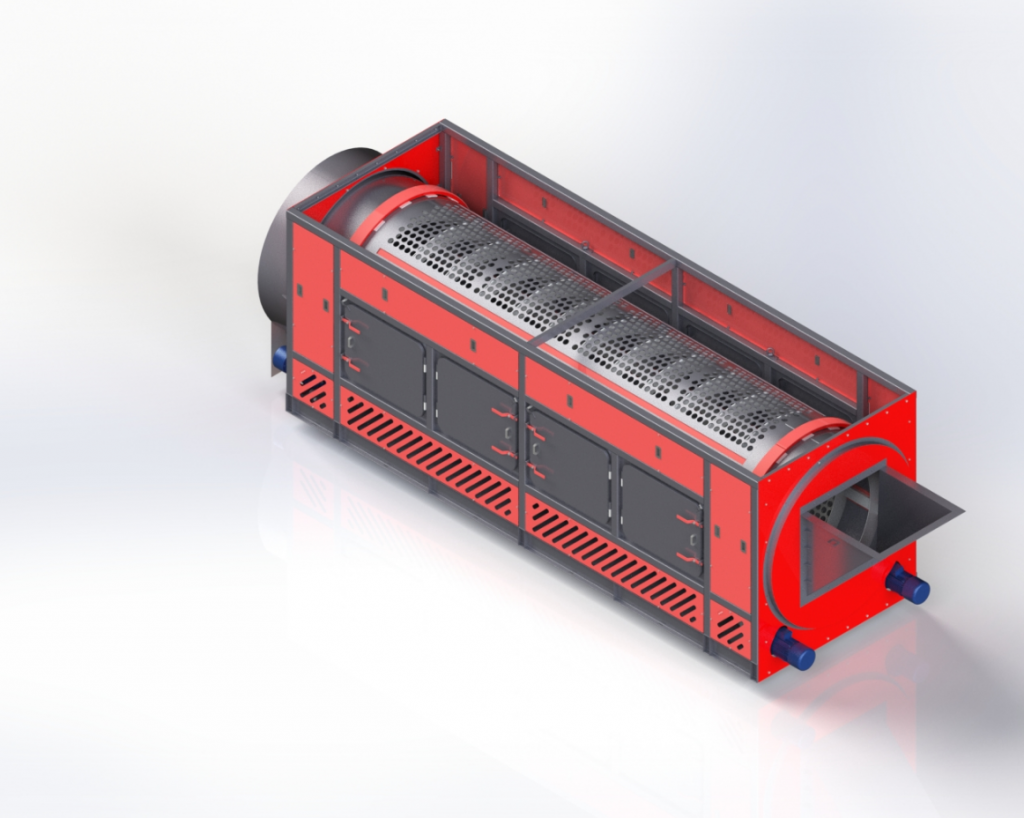

Maintenance of the drum consists in periodic cleaning of its working (perforated) surface, as well as monitoring the condition of the support bandage. Maintenance is carried out through large viewing windows with high-strength locks. The locks are located on the outside, that ensures reliable operation and prevents jamming.

The screen rotation drive consists of two motor-reducers of 11 kW each. Maintenance of drive elements consists of:

- monitoring the condition of bearings;

- control of the drive (according to the accompanying documentation);

- control of the condition of track rollers (lane).

Drive elements are installed in an easily accessible place. If necessary, the drive can be dismantled in a short period of time.

A drive with additional cooling is installed to protect against overheating and shutdowns.

Maintenance of idle and side support rollers consists of:

- monitoring the condition of bearings;

- control of the condition of track rollers (lanes).

- Loading and unloading elements

Quick assembly/dismantling of material loading/unloading allows to eliminate jamming of solid municipal waste.

- Lubrication of bearing units.

Places for lubrication of bearing units are convenient and safe for extrusion.

2.

Weight

One of the main competitive advantages is its weight, which is approximately 10 tons.

3.

Steel wheels.

The support wheels are made of steel to increase the service life.

4.

Installation speed.

The trommel screen can be transported by one truck with minimum dismantling of its components. It provides the fastest commissioning.

5.

Optional offers:

- Cleaning brush.

- Color according to RAL as agreed with the Customer.

- Centralized lubrication

- Manufacture of the trommel from Hardox 450 steel

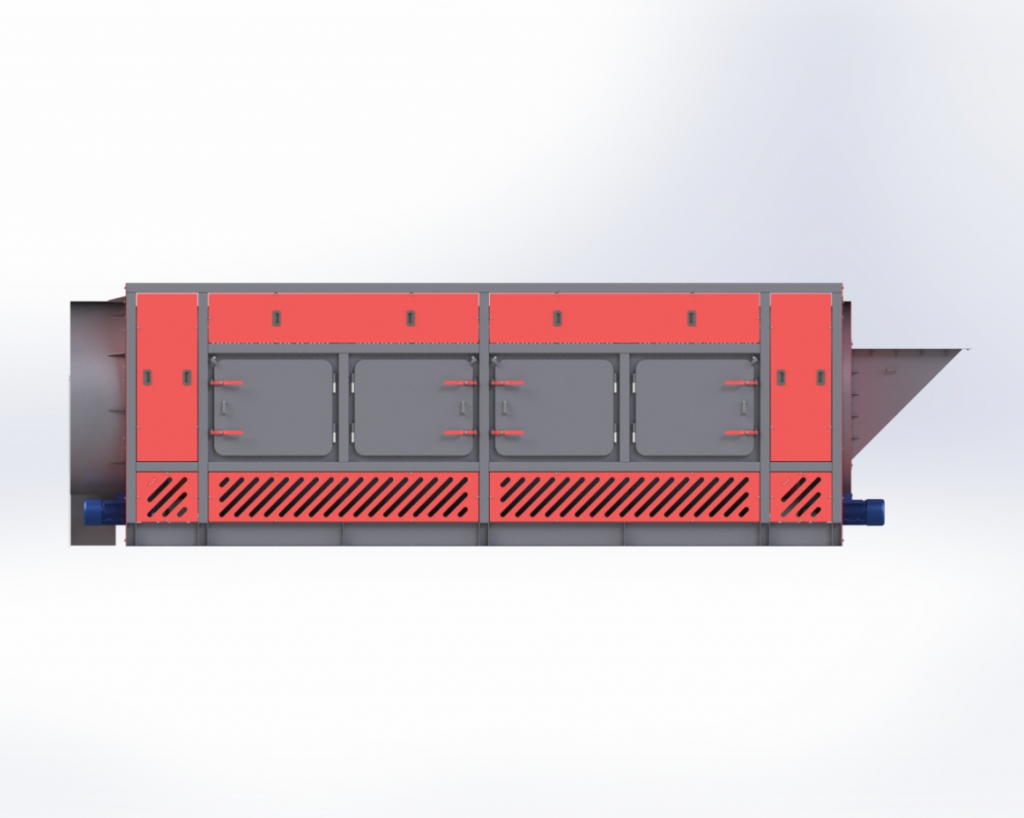

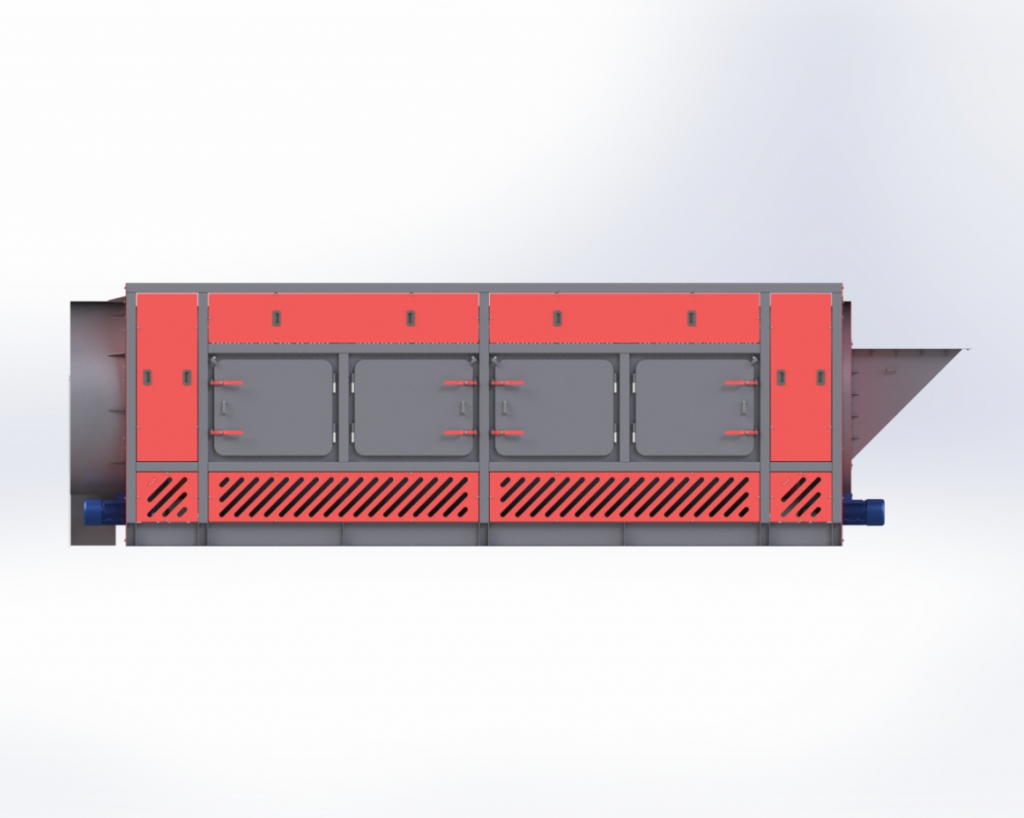

Main technical specifications of the trommel screen